The automotive industry has always pioneered innovation and adopted automation faster and more complete than most other industries. Prompted by things such as fuel efficiency, safety standards and unique design specifications, industrial automation is seeing greater utilization of next-generation metals and new materials. For the automotive world and general fabrication industry alike, this has inspired the creation and perfection of alternative joining methods such as:

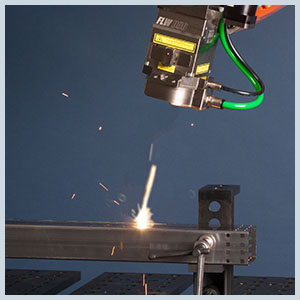

Laser welding

Capable of creating strong, repeatable weld seams at relatively high speed with amazing precision, robotic laser welding is being used for greater productivity on shop floors, giving manufacturers the ability to weld materials that were once seen as non-weldable. Well suited for medium- to large-volume production runs, this process uses a focused laser beam to provide precision heat input and to target weld seams. A good choice for a wide selection of metals with varying thickness, laser welding can be performed via heat conduction (i.e., remote laser welding), deep penetration welding (i.e., laser seam stepper) or hybrid laser arc welding.

Variations to traditional laser welding have emerged as suitable replacements for spot welding. The precision and clean weld seams offer by laser spot or laser seam steppers are ideal for Class A finishes. Lasers, like those used in laser ablation, can also help remove material to prep surfaces for coating.

Options for dissimilar metals

Aside from laser welding, there are several other popular options for the welding of mixed metals that manufacturers are finding beneficial, especially when it comes to cost savings and cycle time.

-

Flow drilling – a very clean, single-sided process that uses a spinning screw to generate heat and friction during the drilling process, melting the base metals and using the screw as filler metal. This method is ideal for joining dissimilar sheet metals such as those used in Electric Vehicle (EV) battery trays or motor mounts.

-

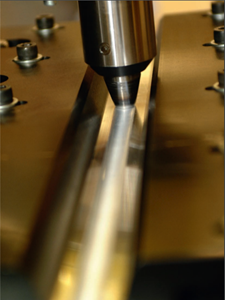

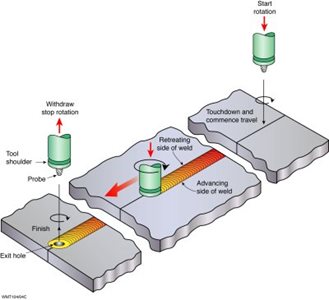

Friction stir welding – a solid-state joining process (where the metal is not melted) that entails a spinning router applying pressure and friction to fuse metals. This method excels at continuous weld seams and requires minimal consumables and no filler metal. It is also ideal for joining alloys or dissimilar metals from 0.5 to 65 mm thick.

-

Brazing – using a traditional GMAW- or GTWA-like process, this process typically employs the use of silicone bronze filler to braze materials, creating a metallurgical bond between two dissimilar metals (i.e., dissimilar steels or steal with aluminum). A low melting point filler metal is flowed onto the base part or joint without distortion. Frequently used to fill voids, or to bond or strengthen parts, this method is suggested for use on parts with deep gaps.

Brazing – using a traditional GMAW- or GTWA-like process, this process typically employs the use of silicone bronze filler to braze materials, creating a metallurgical bond between two dissimilar metals (i.e., dissimilar steels or steal with aluminum). A low melting point filler metal is flowed onto the base part or joint without distortion. Frequently used to fill voids, or to bond or strengthen parts, this method is suggested for use on parts with deep gaps.

-

Friction element joining – enabling the joining of lightweight materials such as aluminum with high strength steel, this method uses a steel friction element to penetrate the upper layer before welding onto the base plate. The friction, that is generated by appropriate process control and the application of mechanical forces, acts directly on the friction element. The produced frictional heat acts on the element and the base plate without reaching the melting temperature, and an adhesive bond is only creative between the friction element and the base plate. This process is beneficial for demanding joining processes found with automotive structural parts.

-

Self-pierce riveting – clinched in one operation, this method uses self-piercing rivets to punch their own holes through harder materials, eliminating the cost of pre-drilling and pre-punching. Ideal for metal-to-metal fastening applications, this process is good for joining low-carbon steels, brass, aluminum and stainless steels.

Find the optimal method for your application!

This arsenal of welding processes gives manufacturers the ability to accommodate evolving customer demands. While the optimal solution for a given task will depend on compatibility, cost and cycle time, the effective use of any of these robotic processes has the potential to increase throughput and product quality.

To learn more about these methods and to discover if implementing one may yield greater productivity gains for your operation, listen to one of our informative webinars on the subject.

-

Alternative Joining Methods for Automotive Manufacturing is led by our in-house expert, Heath Lynnes, and offers a detailed look into the cutting-edge metals being introduced to this space, as well as the weld methods being used to accommodate these new materials. The welding of dissimilar metals is addressed, along with what automotive applications are seeing the greatest benefit from these new processes.

-

Welding Advances in General Industry is a roundtable discussion with expert welding engineers, Van Pratt, Chris Anderson and Heath Lynnes, which covers recent developments for welding in general industry including laser welding, TIG alternatives, brazing and new developments for arc welding.

Josh Leath is a Senior Product Manager

Connect on: