If you’ve recently thought about purchasing a robot to optimize production, then you may have questioned whether a human-collaborative robot (cobot) is right for your application. While a proper risk assessment and following ISO standards should lead the way in the decision-making process, here are some other aspects to consider.

Popular Misconceptions

Frequently, I encounter customers looking to buy collaborative robots based on popular misconceptions:

Easy to Use: some people automatically assume that human-collaborative robots are easier to program. Testimonials have revealed that while hand-guiding is a beneficial feature of a collaborative robot, the main driver of ease of use is due to the robot pendant. For this reason, Yaskawa’s Smart Pendant was designed to be easily programmed by novice users. The Smart Pendant features a number of easy-to-use tools including, Smart Frame technology that allows the robot to adapt to the position of the programmer, eliminating the use of conventional coordinate (X, Y, Z) frames, resulting in easy and efficient robot jogging from the pendant itself.

Currently, Yaskawa is the only robot manufacturer that offers the same easy-to-use touchscreen pendant on both our collaborative robots and our industrial robotic arms.

Less Expensive: another misconception is that collaborative robots cost less to implement. However, an equivalent standard industrial robot is normally significantly less expensive than an equivalent collaborative robot.

No / Minimal Guarding: similarly, many people assume that collaborative robots do not require safety guarding. Again, this is not always the case. While collaborative robots do have internal sensors to detect human presence, sometimes it is necessary to have additional safety measures or guarding in place based on the task being performed. This could mean fencing may be needed in a certain area or that a zone scanner could be required.

Collaborative Quiz

Before reading further, test your knowledge by taking the following quiz:

Which applications can be done safely with a collaborative robot?

a. Machine Tending

b. Polishing

c. Screwdriving

d. Palletizing

e. None of the above

f. All of the above

ANSWER: Based on the information given, there is insufficient information to determine a correct answer. It is really not enough to assume that just because you’re using a collaborative robot that your application can be collaborative. You need to assess the robotic system as a whole. This includes the robot, the end effector, the actual workpiece and the entire workspace. It is vital that all of these be taken into account before the application can be determined as collaborative. And, once again, no matter what kind of robot you use, it is imperative to participate in a thorough risk assessment in accordance to the ISO standards (ISO 10218-1 & ISO 10218-2 and ISO/TS 15066) for every robotic installation.

If you are not able to do a risk assessment internally, there are a number of companies that specialize in doing. This includes Pilz Group, SICK and others as well.

Risk Assessment Criteria

The main difference between a risk assessment for a standard, industrial robotic system and collaborative robotic system risk assessment is that now you have to account for intended and foreseeable human contact with the robotic system while the robot is in motion. Of course, you cannot just consider contact as a whole, you need to account for interaction between the robot and each body part that may impact the robotic system. This includes:

Transient Motion: free-space movement (from point A to point B).

Quasi-static Motion: pinching or clamping forces.

Pressure and Force Applied: not just the force in newtons (N), but also the maximum permissible pressure value that is listed in N/cm

2.

Frequency and Duration of Contact: this is outlined in ISO/TS 15066 – see the chart that gives all of the maximum permissible forces and pressures for every body part.

Collaborative Robot Overview

Modes of Collaboration

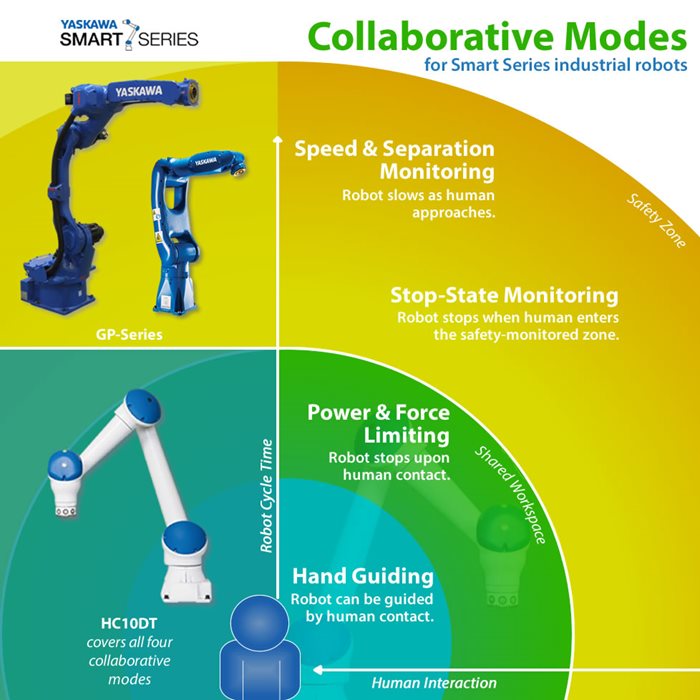

Having a clear understanding of the four modes of collaboration is extremely helpful when deciding whether an industrial or collaborative robot is needed. While this blog focuses mainly on Power and Force Limiting, technically, any one of the following features qualifies a robot as collaborative.

1) Stop-State Monitoring: robot stops when human enters the safety-monitored zone.

2) Speed & Separation Monitoring: robot slows as human approaches.

3) Hand-Guiding: robot can be guided by human contact.

4) Power and Force Limiting (PFL): internal sensors stop the robot movement upon human contact.

Collaborative Robot Design Factors

A key question to answer is, “What really makes a PFL-type robot collaborative?” This can be answered by looking at the unique ways a particular robot is designed.

1) Collaborative (Power and Force Limiting systems, smooth surfaces,

pinch-less design)

For example, the Yaskawa

HC10 robot is designed to be collaborative. It has smooth surfaces with no exposed sharp edges, and it is also completely pinch-less—designed so that a human hand can be placed under the robot arm without being pinched or clamped in any way. Plus, this cobot features built-in, safety-rated Power and Force Limiting sensors in the form of two torque sensors for every axis. Similarly, these torque sensors are constantly monitored to be sure they do not exceed the pre-set thresholds.

2) Not Collaborative (protrusions, no PFL, pinch points)

In contrast, when looking at the

GP8 industrial robot, you will notice some difference. While it does look a bit smooth, there are some protrusions that stick out on the upper arm, as well as the back of the robot (not shown). This robot also has pinch points, where a human hand can be pinched when the robot is in operation. While the GP8 robot does have collision detection, it is not equipped with a built-in, safety-rated Power and Force Limiting sensor system – meaning, the robot will stop if there is an impact, but it cannot be used for safety purposes.

Collaborative Gripper Qualifiers

Paying attention to gripper or end effector design is equally important, as seen with the following examples from SCHUNK.

1) Collaborative

Collaborative grippers are made for safe human interaction. This example shows a plastic-coated gripper, meaning there are no sharp edges. There is also a visual indicator/light, verifying when the gripper is in collaborative mode. Collaborative grippers must also have built-in, safety-rated Power and Force Limiting, and they must be adjustable for different points of contact. Keep in mind that 150 newtons of force is the limit for hands – meaning the gripper must be adjustable, so that it does not clamp down on a human hand at greater than 150 N of force, avoiding injury. While this is just one example of gripper, there are a variety of

collaborative grippers out there to suit your particular applications.

2) Not Collaborative

2) Not Collaborative

At first glance, a gripper or end effector may seem collaborative, but further inspection is always required. Non-collaborative grippers will have features like sharp edges and protruding bolts. The gripper fingers may also be made of metal, such as aluminum, making it an unsafe option for human interaction.

Collaborative Part Qualifiers

The part(s) that will be used in the application must also be considered. If it is something like a box, you will probably be okay, unless it is filled with something dangerous like corrosive chemicals or an object that could expose sharp edges when dropped. Similarly, a glass bottle that can easily break does not fit the criteria. You must also consider the part before and after any kind of operations – because once an operation is done, you could have sharp edges that could potentially hurt someone. Keep in mind that 150 newtons of force from something the size of a basketball would feel a lot different than something the size and shape of pen or a knife.

Example: if you have a piece of deburred metal that is going into a mill or punch that is making knife blanks, caution must be raised. While the blades may not be sharp yet, they are still somewhat pointy. This opens up the possibility for human injury – as a point could exert enough pressure on a human hand or body to cause damage. Despite ways of getting around this issue – maybe by shielding the points within the gripper or pulling the points up into a protective cage or section – this is a serious matter to consider.

Collaborative Job Limitations

Another aspect that must be weighed is the job itself. Items to consider are:

1) Speed: while in collaborative mode the safest speed of Tool Center Point (TCP) that the robot can travel is 250mm/s (second). Depending on the job, this may be slower than desired.

2) Human Head Impact: during a collaborative application, the robot is not allowed to impact a human head.

3) Biomechanical Force / Pressure Limits: during a collaborative task, the robot cannot exceed the biomechanical force or pressure limits of any body parts that the robot system may encounter.

Other Considerations

Productivity

This is perhaps the biggest consideration. As mentioned, the safest speed for the Tool Center Point (TCP) of a collaborative robot to travel is 250mm/s. Whereas, with a standard industrial robot the speed is about four times faster in excess of 1,000mm/s.

Several cobots, including Yaskawa collaborative robots, allow switching in and out of collaborative mode using a zone scanner to detect human presence. This can really increase your speed, that way you’re not losing any productivity from being in collaborative mode.

This brings up the question:

if you’re going to be using a zone scanner anyway, why not use a standard industrial robot, instead of a collaborative one?

The biggest differentiator is that a collaborative robot can continue to operate with a human in the work area. Whereas, an industrial robot must arrest motion completely when someone enters the work area. This one key factor makes the decision relatively straightforward. If the robot must continue operation, then you definitely need a collaborative robot, but if the robot is able to stop, the choice whether to use a collaborative robot or an industrial robot is yours.

Cost

Another important factor is cost.

1) Cost of Industrial Robot vs. Collaborative

Due to the additional safety-rated sensors, collaborative robots can be thirty to forty percent more expensive than an equivalent industrial robot. As mentioned, the

Smart Pendant is available for all robots in the Smart Series product line. This includes the industrial MotoMini, GP7, GP8 and GP12 robots, as well as the collaborative HC10DT robot. This group is unique in that the same easy-to-use features found on the Smart Pendant are carried over into the GP-series robots listed.

2) Cost of Laser Zone Scanner

No matter if a collaborative robot or an industrial robot is chosen for a particular application, a laser zone scanner is often selected, making it a sunk cost. Even so, laser scanners usually cost only few thousand dollars, making them relatively economical. Furthermore, it is a very cost-effective way to enable collaborative operation without the additional expense of a collaboratively-rated robot.

Moving Forward Into collaborative

All things considered, I highly recommend pricing both collaborative and industrial robot options to ensure you are making the best choice for your application and your company – making sure you get the best return on your investment! If you are interested in learning more about specific

application examples, listen to our

webinar, take the

Robot Matchmaker Quiz, or if you have further questions about your specific application, please

contact our experts.