Increasingly used by different industrial sectors and radically changing the way many products are made, additive manufacturing (AM) continues to be a driving force for advanced manufacturing prototyping and production. Expected to grow at a compound annual growth rate (CAGR) of 20.8 by 20301, this process of using digital design data to successfully create solid three-dimensional objects by fusing layers of material together (aka: 3D printing) allows a great deal of flexibility in the production process, continuing to impact the industrial landscape.

Whether it is tooling for composites, prototype aircraft or automobile parts, product designs once thought too complex are now becoming a reality – thanks to more accurate and reliable 3D printing technology. Along with this, advancements in motion control, power conversion and robotics are all helping to expand the scope of AM, enabling the fast creation of sophisticated, durable objects through methods such as Selective Laser Melting (SLM), Fused Deposition Modeling (FDM) and Binder Jetting.

Basic desktop 3D printers and those with stair stepper motors are giving way to servo-controlled 3D printers with high resolution feedback, allowing for high-speed position, velocity and torque control. Six axis robots with few limitations to potential printing angles, as well as robust gantry systems for large structure printing, are also being incorporated to complement this process, causing manufacturers to take another look at the possibilities this process and technology can bring.

Key Benefits

Especially helpful for manufacturers needing one-off parts or fixtures, additive manufacturing is ideal for repairing old parts, customizing production parts or prototyping/modeling new ones. Similarly, companies may use 3D printing as part of their engineering design process, tooling and fabricating unique geometries in-house. Whatever the reason, AM offers multiple benefits, including:

Flexible Production – small scale manufacturing thrives on being able to adapt and leverage design freedom. 3D printing’s ability to incorporate more than a hundred diverse materials and produce nearly any shape makes this a fab shop must have. Designers can also significantly reduce the number of individual parts used in an assembly, eliminating potential failure points for increased durability.

Cost-Reduction – the additive process is less labor intensive, and overall, it reduces the amount of raw material used, saving valuable resources and money. For example, by only “printing” the primary share of the part, this process eliminates a lot of waste from machining away a small percent of your raw material rather than machining away a majority of unneeded material from a billet of metal. Typical wire arc additive manufacturing (WAAM) robotic arm systems can also be less expensive than powder-based AM printers. The Center for Advanced Manufacturing (CAM) at University of Southern California (USC) Viterbi School of Engineering has been utilizing WAAM for this very research, while reducing time and cost for a variety of parts and tooling.

Production Efficiency – with sluggish supply chains, 3D printing offers an affordable and timely alternative than waiting weeks for much needed parts to arrive on the production floor, especially for “quantity 1” custom parts. Additive manufacturing requires far less downtime, helping manufacturers to produce parts or tooling on-demand, maintaining throughput for on-time delivery and project deadlines.

Other Notable Factors

Material Considerations

The variety of compatible materials available for 3D printing is also helping to optimize this process. From plastic to plaster, there are a lot of viable options to fulfill unique application requirements. Even food-grade options are starting to transform the food industry.

Popular with robot usage, the process of wire arc additive manufacturing uses metal filler wire in a GMAW process to produce conformal steel structures. Competing with traditional laser processes, new methods offer the higher resolution by substituting wire for use of metal powder that facilitates a smoother end product with less lines. Also enabling higher end parts is the use of enhanced high-deposition printing heads that are so precise that little finishing and polishing is required.

Innovative Solutions

To aid the additive process, offline programming platforms with 3D printing software act as a link between the digital model and the actual model created. Known as 3D printing slicer software, these platforms help transform the digital model into printing instructions, called G-code.

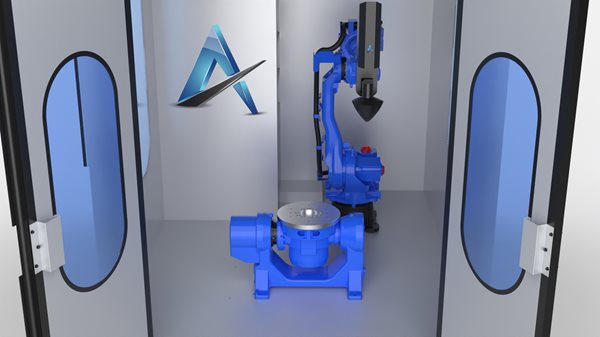

Companies, like ADDiTEC, take additive manufacturing a step further, offering an intuitive human machine interface (HMI) with a high-performance printing robot. This comprehensive solution gives the unique ability to process two wire materials in a single part, along with the capability of printing powder and wire materials at the same time, making the process ideal for the creation of highly complex components from demanding materials. Other solutions for conventional parts are available as well.

Accessible Manufacturing

As manufacturing methods and advanced technology evolve, expect more robots to be used for 3D printing – as a majority of commercial 3D printers (plastic, metal and other) are very expensive and are relegated to one specific job with a specific print area size. Not only do robots add a plethora of flexibility for part size options, but also, they allow for upgrading print heads, as needed. A seventh axis can even be added for an extremely large part. This is especially helpful with creating a large range of parts, such as remote service facilities and prototyping.

Overall, the use of additive – especially when used with robots – is an expedient, cost-effective option for various applications. Whether a university is printing molds for carbon fiber layups or a large equipment manufacturer (i.e., mining, construction, etc.) needs to create a part in a pinch to complete an order, the flexibility 3D printing provides makes the manufacturing of parts more accessible for fluid production.

1 Additive Manufacturing Market Size, Share & Trends Analysis Report, Research and Markets, 2022

Images provided courtesy of Rivelin Robotics and ADDiTEC

Josh Leath is a Senior Product Manager

Connect on: