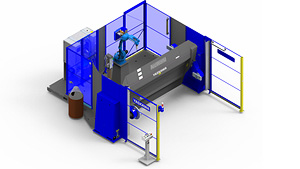

Ultimate in Automation

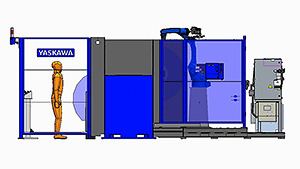

Indexing ferris wheel offers the smallest footprint and fastest cycle time, while offering coordinated motion and easy tooling swaps in a maintenance-free postioner design.

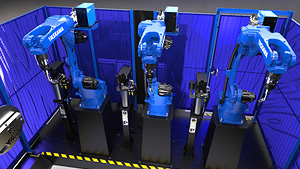

HyperProductivity®

Accommodates up to three AR1440 or AR2010 robots for maximum arcs on in a efficiently-sized workcell to give you faster cycle times and more parts produced.

Safety First

All of our ArcWorlds have completed risk assessment and meet or exceed all RIA and ANSI requirements to keep your employees safe and OSHA satisfied.

Terms of Use and Copyright Notice

This content is freely available as a service to Yaskawa customers to assist in the operation of Yaskawa Motoman robots, related equipment and software. All content is copyrighted property of Yaskawa and may not be sold or redistributed in any way. You are welcome to copy these documents to your computer or mobile device for easy access but you may not copy them to another website, blog, cloud storage site or any other means of storing or distributing online content.

All downloading activity is logged. Downloading content from this page indicates that you understand and agree with the above terms of use.